How to Make a Small Economy Bat House

Materials Needed

- ¼ sheet ( 2′ × 4′ ) ½ ” AC, BC, or T1-11 (outdoor grade) plywood. DO NOT use pressure treated wood.

- One piece 1″ × 2″ (¾” × 1½ ” finished) × 8′ pine (furring strip)

- 20 – 30 1¼ ” coated deck or exterior-grade Phillips screws

- One pint dark, water-based stain, exterior-grade

- One pint water-based primer, exterior-grade

- One quart flat water-based paint or stain, exterior-grade

- One tube paintable latex caulk

- 1″ × 3″ × 28″ board for roof (optional, but highly recommended)

- Black asphalt shingles or galvan ized metal (optional)

- 6 – 10 7/8″ roofing nails (optional)

Recommended Tools

- Table saw or handsaw

- Caulking gun

- Variable speed reversing drill

- Paintbrushes

- Phillips bit for drill

- Tape measure or yardstick

- Scissors (optional)

- Staple gun (optional)

Construction Procedure

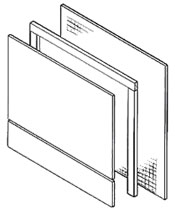

- Measure and cut plywood into three pieces:

26½” × 24″

16½” × 24″

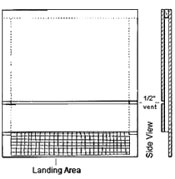

5″ × 24″ - Roughen inside of backboard and landing area by cutting horizontal grooves with sharp object or saw. Space grooves about ½” apart, cutting 1/16″ – 1/32″ deep.

- Apply two coats of dark, water-based stain to interior surfaces.

Do not use paint, as it will fill grooves, making them unusable. - Measure and cut furring into one 24″ and two 20¼” pieces.

- Attach furring strips to back, caulking first. Start with 24″ piece

at top. Roosting chamber will be ¾” wide (front to back). - Attach front to furring strips, top piece first (don’t forget to caulk). Leave ½” vent space between top and bottom front pieces.

- Caulk around all outside joints to further seal roosting chamber.

- Attach a 1″ × 3″ × 28″ board to the top as a roof, if desired (optional, but highly recommended).

- Paint or stain exterior three times (use primer for first coat).

- Cover roof with shingles or galvanized metal (optional).

Optional Modifications to the Small Economy Bat House

- Wider bat houses can be built for larger colonies. Be sure to adjust dimensions for back and front pieces and ceiling strip. A ¾” support spacer may be required in the center of the roosting chamber for bat houses over 24″ wide to prevent warping.

- Two bat houses can be placed back to back, mounted on poles. Before assembly, a horizontal ¾” slot should be cut in the back of each house about 9″ from the bottom edge of the back piece to permit movement of bats between houses. Two pieces of wood, 1″ × 4″ × 4¼”, screwed horizontally to each side, will join the two boxes. To provide additional roosting space, leave a 3/4″ space between the two houses, and roughen the wood surfaces or cover the back of each with plastic mesh. (Do not cover the rear exit slots; see item 4 below). One 1″ × 4″ × 34″ vertical piece attached to each side over the horizontal pieces blocks light, but allows bats and air to enter. A galvanized metal roof, covering both houses, protects the center roosting area from rain. Eaves should be about 3″ in southern areas and about 1½” in the north.

- Ventilation may not be necessary in cold climates. In this case, the front should be a single piece 23″ long. Smaller bat houses like this one will be less successful in cool climates. However, those mounted on buildings gain heat faster, maintain thermal stability better and are more likely to attract bats.

- Durable plastic mesh can be substituted for roughening to provide footholds for bats. Attach one 20″ × 24½” piece to backboard after staining interior, but prior to assembly.

Special thanks to Bat Conservation International for allowing us to use their plans for building a bat house. To learn more about bats visit their web site at: http://www.batcon.org

Learn more about bat pest control.

Go back to the bat removal page.